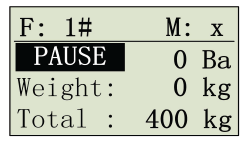

Turn "Manu./Auto." switch to "Auto." (set each Parameter in advance), the instrument would display as follows:

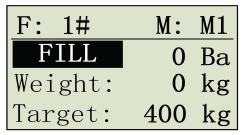

Press "Run" to start batching and instrument would display as follows:

(4)If you want to remove the surplus material, it is required to turn "Manu./Auto." switch to "Manu." for safety.

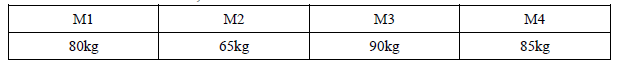

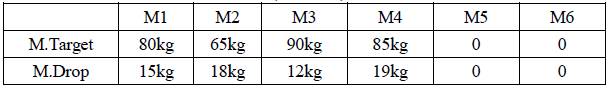

In order for user to know well about the operation methods of the batching controller, this "Application Examples" is written and the user may know well the installation and parameter setting of this instrument. For instance, a concrete batching site is designed to manufacture a mixture of 4 materials, with contents of each is described as below:

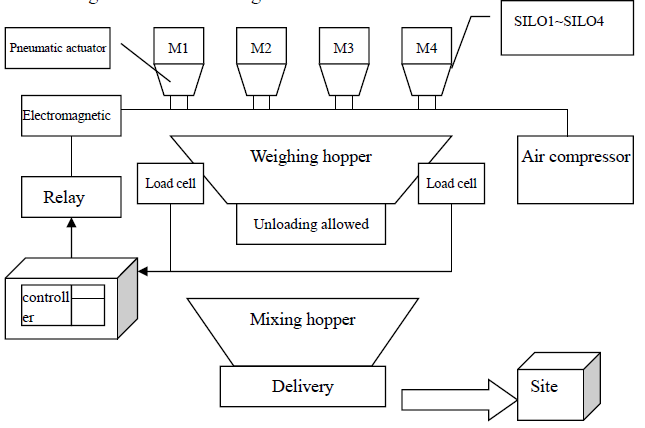

Batching mechanism is designed as below:

Each material was delivered from feeding mechanism to SILO, a pneumatic actuator controlled by electromagnetic valve at the bottom of SILO is designed to control the charging amount or inching compensation charging or stop charging. In addition, electromagnetic valve is controlled by relay. After starting batching, the material in the SILO is discharged into the weighing hopper by opening SILO gate while weighing each materials in weighing hopper in turn. After all materials are weighed, they would be automatically discharged to mixing hopper (in automatic discharging mode), on the other hand, materials would not be discharged unless "P.Disc.Input"/"R.Disc.Input" input is effective (in Manual discharging mode). Mixed materials in mixing hopper would be delivered to transport vehicle by delivery mechanism and then to the working site, a batching process is finished.

Setting working parameters:

OpenDelay: 1s

Imp.Delay: 0.4s

Closed Dly: 4s

Disc. Dly: 5s

Fullscale: 400Kg

Comp.Time: 0.2s

ZeroRange: 3.0%

OverLoad: 3%

PE Range: 1%

Disc.Mode: Manu.

Drop Mode: Manu.

Others with default value.

Def.Form.: 1 F.Batch: 0 (no limit)

Shen Zhen Zhuohe Instrumentation Co.,Ltd was founded in year of 2002.We specialize in providing BATCHING CONTROLLER,BELT SCALE CONTROLLER,PACKAGING CONTROLLER and WEIGHING TRANSMITTER.

If you are interested in our products, welcome to contact us via email.

Contact: Celia

Phone: +86-13825212800

Tel: +86-13825212800

Email: sales3@meterforall.com

Add: Floor 6 ,Building 11,Longbi Industrial zone, Bantian Street, Longgang District, Shenzhen, China